Sadly, when I went through my stuff - moving everything to another rejig of my work area - I discovered that most of the paint and glue had not survived their three years holiday. I was particularly concerned about finding a match to the already painted shelves for the library. They needed touch ups and the new trim for the top edges needed painting. My memory of doing Dalton House was that I mixed several paints or at least let down the colour with some white every time I painted a wall or piece of furniture, so the paint for my shelves could, quite literally, be totally unique.

One paint which had survived the stash was a tester Dulux called Melon Sorbet. The name seemed very familiar so I whooped with the expectation that was the one I used.

I tested a little on a hidden section of the shelving and even let it down with some white but it clearly wasn't in the same family at all.

The brain is a totally weird thing for sure - days later and for no particular reason I decided the paint had been one from The Little Greene Paint Company and called Eu de Nil. These are super nice quality paints. £4 a sample tin but no postage and a good size.

As it turned out getting this sample proved ridiculous - I ordered it, it never arrived, I chased it up, two emails not answered, I phoned them - said they would UPS a replacement that day - that never turned up either, another phone call and another UPS replacement promise. Fortunately that one arrived. It took a month from order to arrival!

Having said all that, I don't want to deter anyone in the UK who might be looking for lovely quality paint in a nice quantity for your projects. My previous experiences with them have all been excellent.

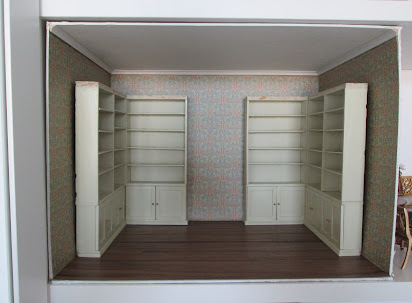

Elf had sent me a trim for the front edges - sadly they had run out of the one I had originally. after much deliberation I decided against it. The previous top trim had served two purposes - trimming the edge and making the shelves reach the ceiling. These shelves of course had been made by Elf to fit the dimensions of that room.

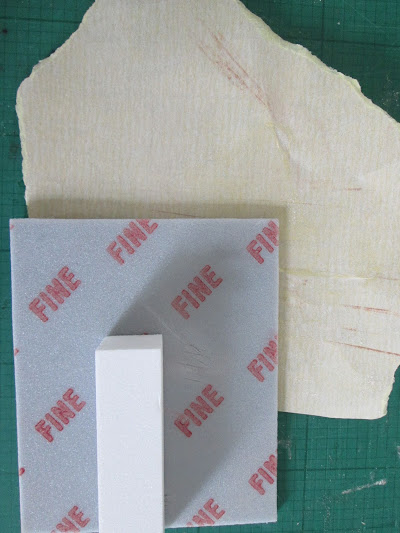

These room boxes are taller so that wasn't going to happen and the new trim was a bit 'fancy', so I decided to just sand the front edges and touch up along with the dints.

The dents along the sides were from using a screwdriver to lever out the shelves which I had judiciously super-glued to the library wall in Dalton House - they would never need moving!! They positively screamed damage when set against the side walls.